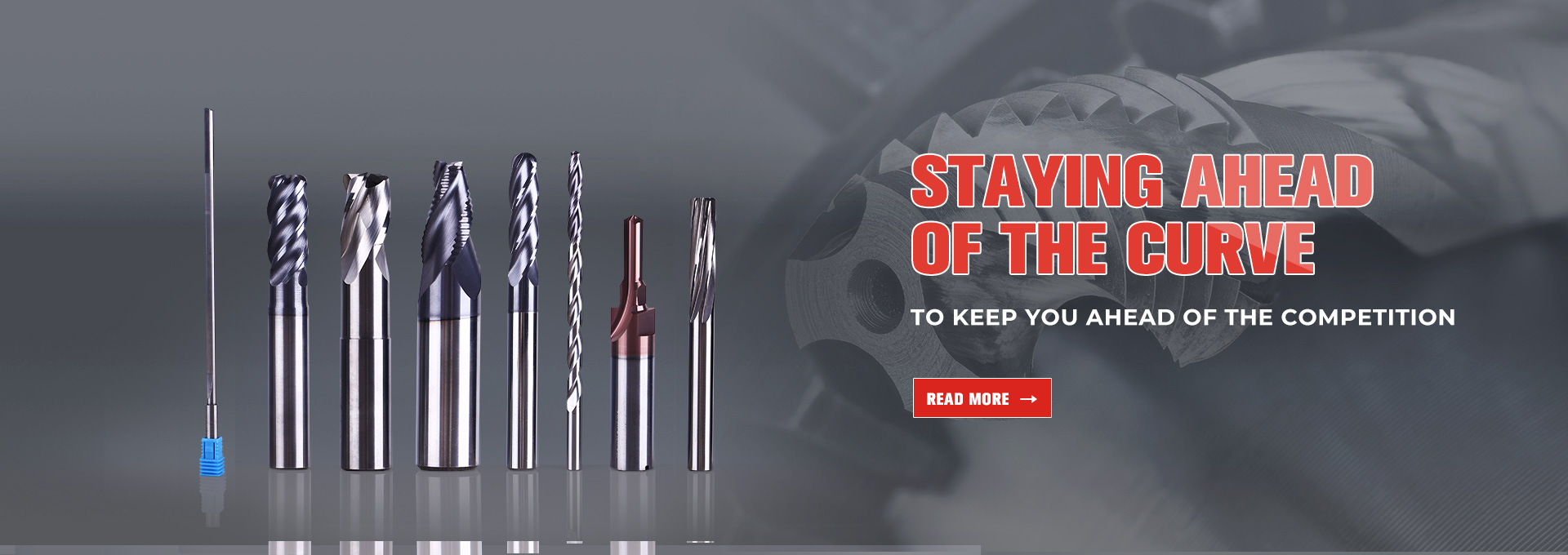

OPT CUTTING TOOLS CAN PARTNER

WITH YOU EVERY STEP OF THE WAY.

From selecting and configuring the right

cutting tools for your job to helping you finance the purchase that generates noticeable profits.

cutting tools for your job to helping you finance the purchase that generates noticeable profits.

MISSION

STATEMENT

OPT CUTTING TOOLS will enhance the value of our customer experience at every level of our organization.

We will accomplish this by providing innovative, world-class products backed by customer-focused services and support.

Our goal is profitable growth through exceeding the expectations of our customers every day.