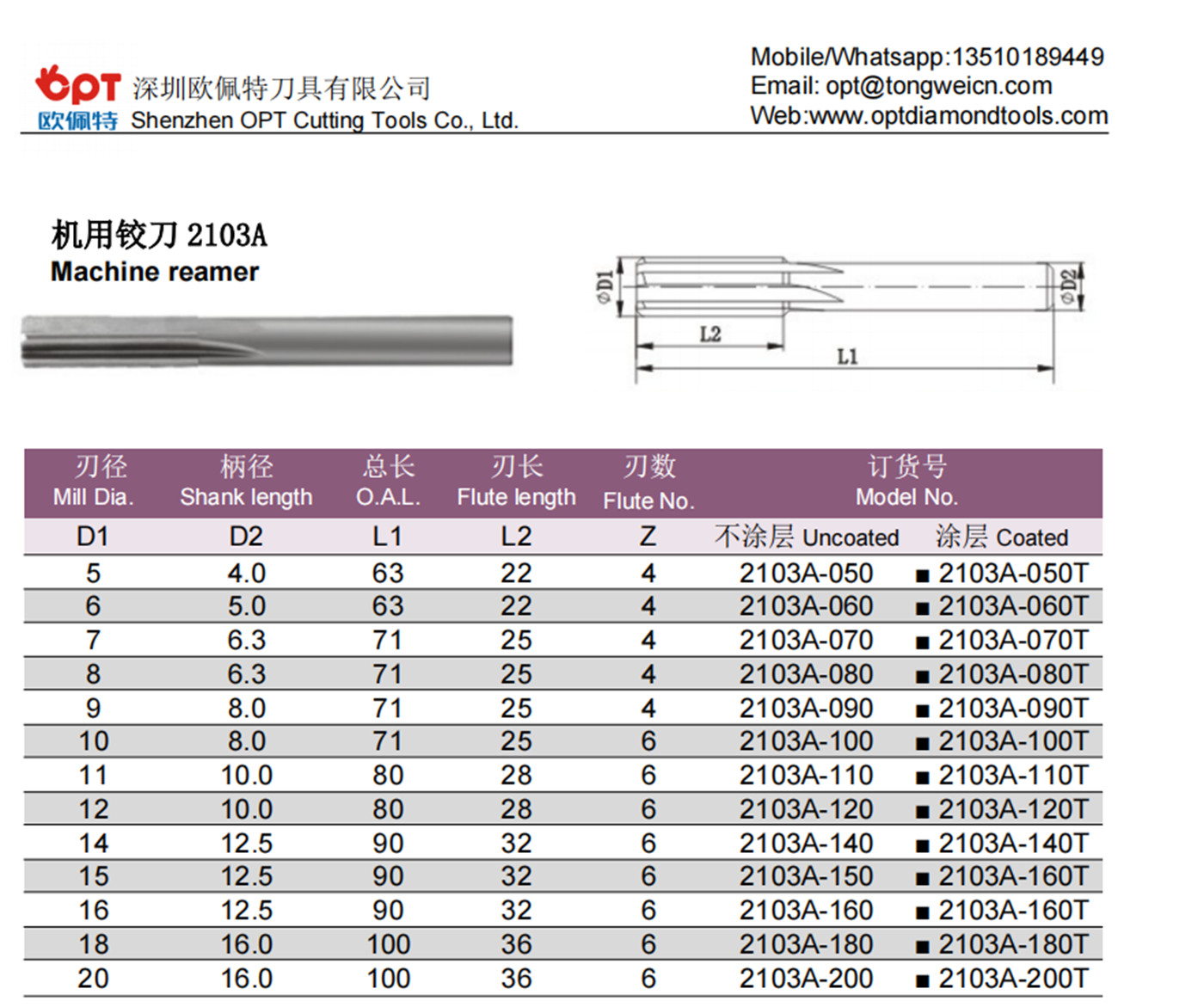

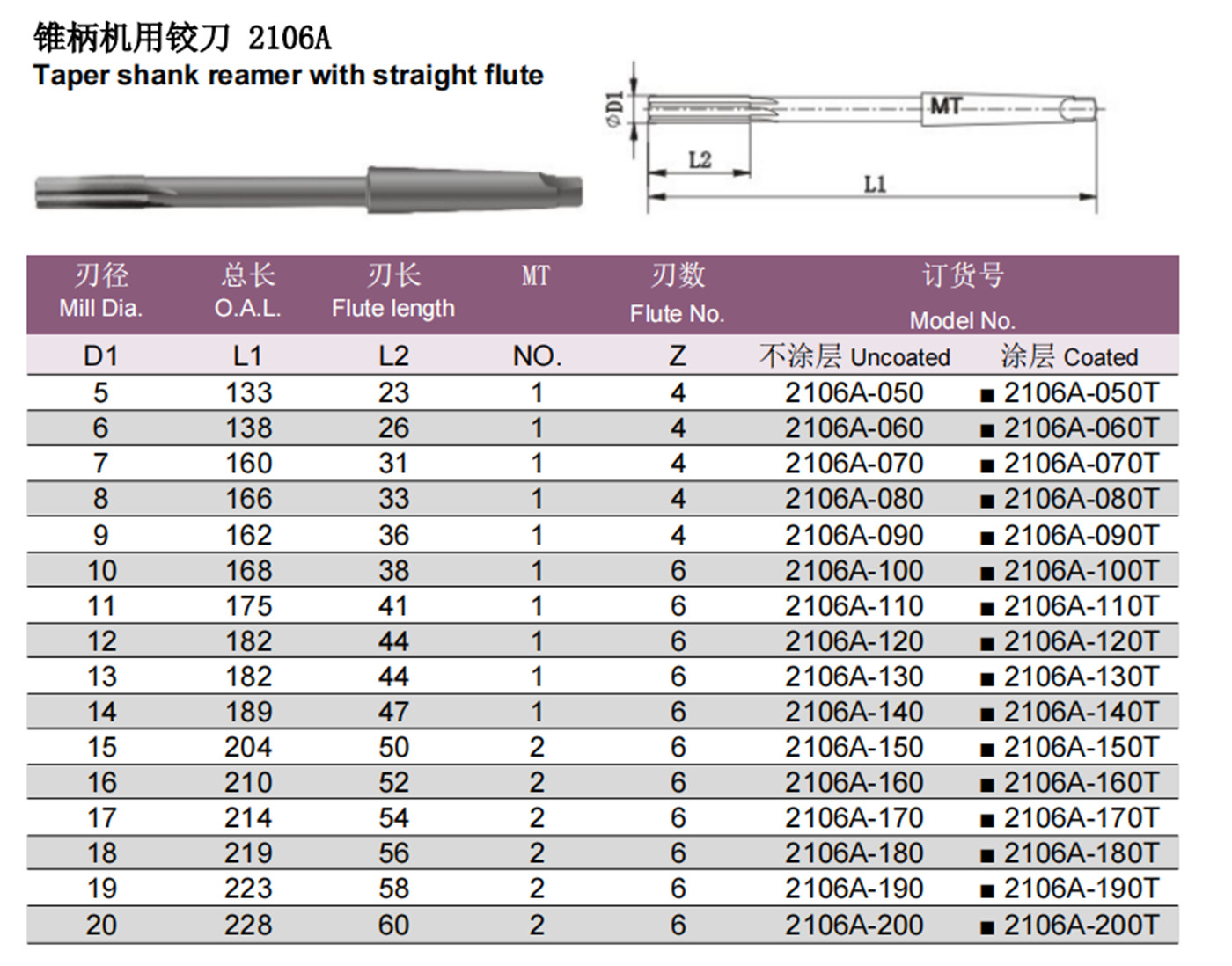

Finishing with carbide machine reamer

Product advantages

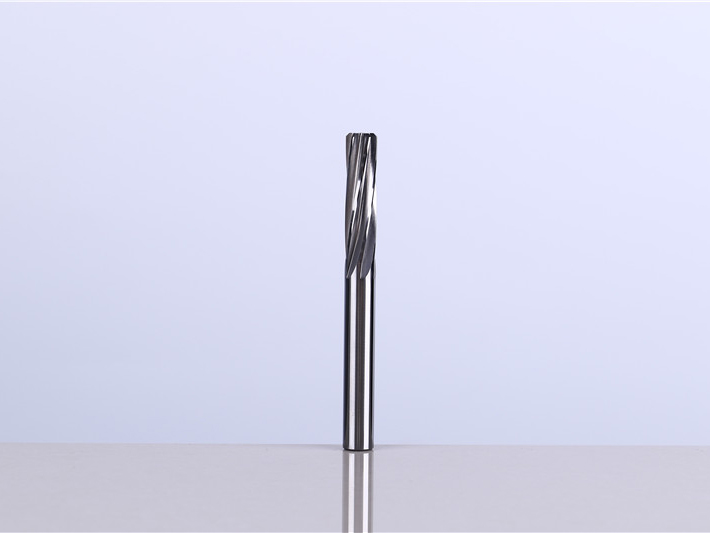

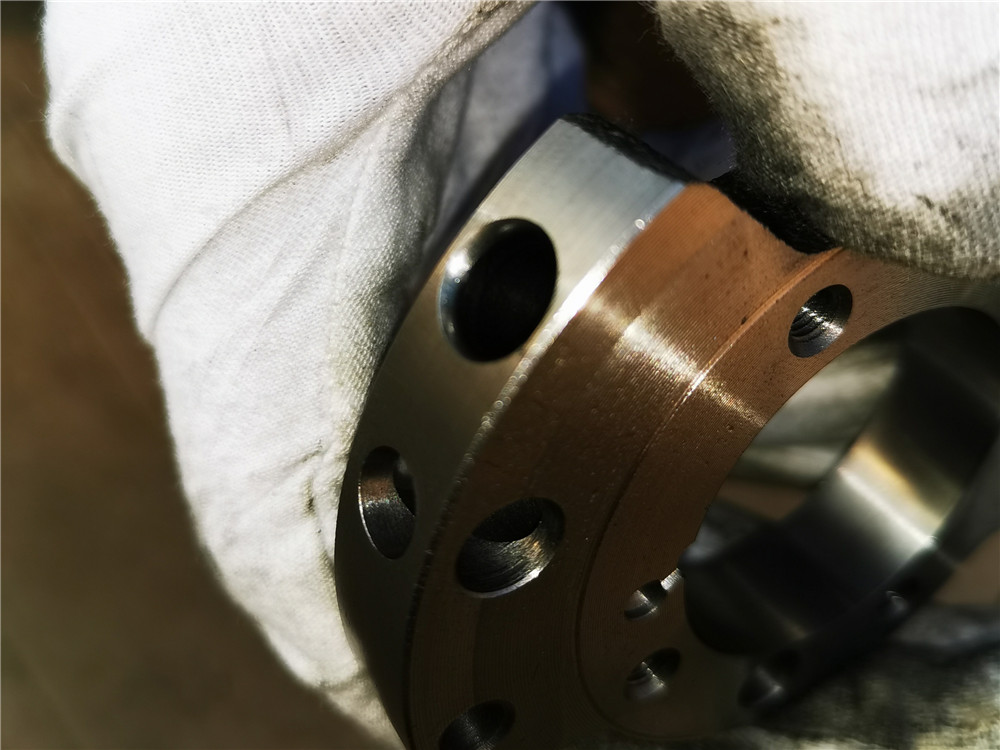

The technology of OPT can be deposited for a longer time, and innovative technologies can be adopted to improve the finish;

The processing method of the milling edge at the bottom of the reamer can ensure not only the finish of the hole, but also the burr of the hole.

Edge taper and passivation processing, is other peers can not match the meticulous

Product Application Range

Excellent adhesion between coating and substrate ensures the stability of processing. Smooth coating surface reduces cutting resistance and improves tool wear resistance

Suitable for: steel, stainless steel, aluminum, cast iron. Titanium alloy. High-hard steel and difficult materials, widely used in aerospace, automobile manufacturing, mobile phone manufacturing and construction machinery

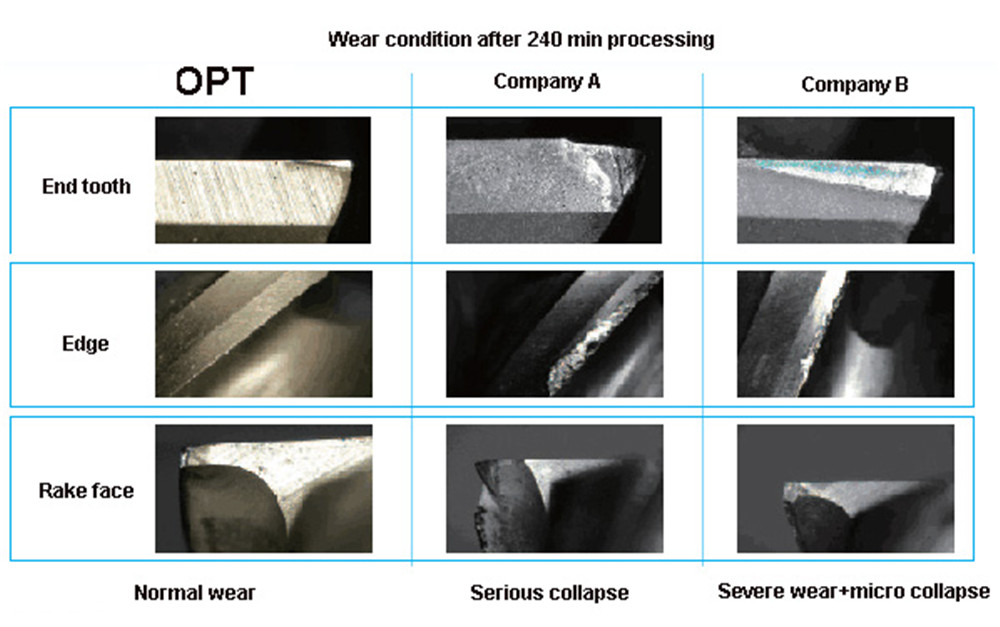

Comparative Advantages of Peers

Carbide reamer edge with a new treatment, blade belt and coating also according to different materials, using different treatment, compared with peers, our tool life is longer, quality is more stable

Custom reamer of various specifications, according to customer's material requirements, coating requirements, cutting edge requirements to customize! The specifications of the handle can also be done according to the requirements of the customer's machine tool, as far as possible to meet different customers, different needs

Functional Advantage

Our tungsten steel reamer processing products good finish, can replace hob and extrusion tool, greatly improve the processing efficiency, improve the competitive advantage of enterprises! Customers used to use coarse hinge and roll, now just a reamer! Reduced equipment and workload!