Carbide Step Drill For Stainless Steel And Aluminum

Product application

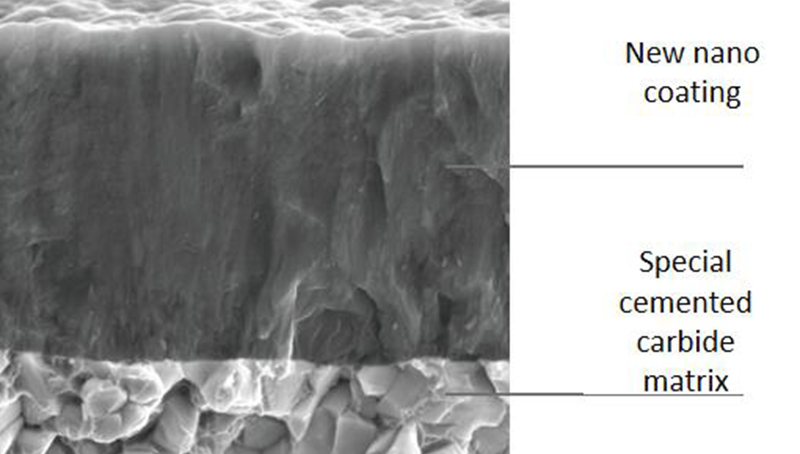

Excellent adhesion between coating and substrate ensures processing stability and prolongs tool life

Smooth coating surface reduces cutting resistance and improves tool wear resistance

Suitable for: Steel, stainless steel, aluminum, cast iron and high hard steel,Widely used in aerospace, automobile manufacturing, mobile phone manufacturing, chip packaging and other industries.

Product advantages

OPT is different: a pioneer in technology and innovation for more than 25 years.

The coating used by OPT is 40% stronger than the ordinary coating.

New "nanostructure" coating technology is adopted, and the coating structure is compact.

Excellent adhesion between coating and substrate ensures processing stability and prolongs tool life.

Smooth coating surface reduces cutting resistance and improves tool wear resistance.

1.The tip of the carbide bit is easy to crack

2.The point is drilled with a reinforced tungsten steel bit

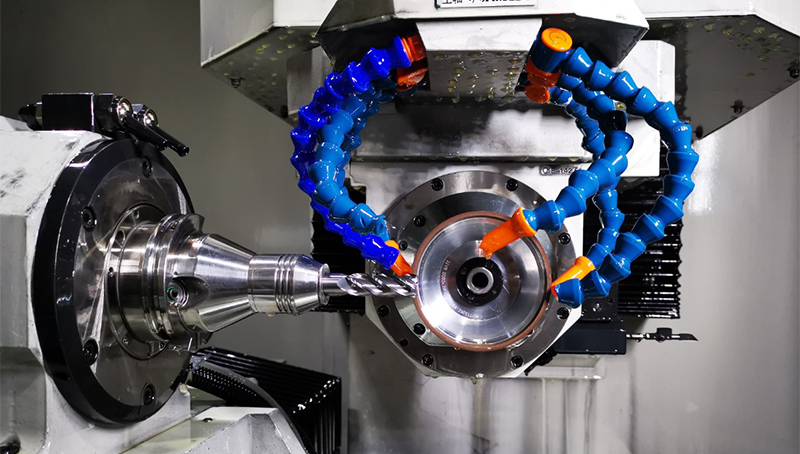

You can use specially developed application tools that are used by trained professionals

Technology tell your production technicians. You can also tell us your needs, our company to provide you with a full set of solutions

Our production workshop production equipment grinding tungsten steel CNC grinding machine, tap grinding machine, CNC grinding machine grinding reamer and milling cutter, of course, there are a variety of professional design and production personnel

|

Bit diameter range d1(m7) |

Drilling depth ratio(1/d) |

Cooling mode |

Shank form |

Ordering model |

Basic dimensions(mm) |

remarks |

||||

|

Shank diameter |

Total length |

Slot length |

Recommended drilling depth |

coating |

||||||

|

d2(h6) |

11 |

12 |

13 |

|||||||

|

2~2.5 |

3 |

External cooling |

Straight shank |

d113*d2*11*3D |

3 |

58 |

13 |

9 |

||

|

5 |

External cooling |

Straight shank |

d1*13*d2*l1*5D |

3 |

58 |

18 |

14 |

|||

|

2.55~2.95 |

3 |

External cooling |

Straight shank |

d113*d2*11*3D |

4 |

58 |

13 |

9 |

||

|

5 |

External cooling |

Straight shank |

d1*13*d2*11*5D |

4 |

58 |

18 |

14 |

|||

|

3~3.5 |

3 |

External cooling |

Straight shank |

d1*13*d2*11*3D |

4 |

62 |

20 |

14 |

||

|

5 |

External cooling |

Straight shank |

d1*13*d2*11*5D |

4 |

66 |

28 |

23 |

|||

|

3.6~4 |

3 |

External cooling |

Straight shank |

d1*13*d2*11*3D |

4 |

58 |

20 |

14 |

||

|

5 |

External cooling |

Straight shank |

d113*d2*11*5D |

4 |

66 |

28 |

23 |

|||

|

8 |

Internal cooling |

Straight shank |

d1*13*d2*l1*8D |

4 |

72 |

34 |

29 |

|||

|

4~4.9 |

3 |

External cooling |

Straight shank |

d113*d2*11*3D |

5 |

66 |

24 |

17 |

||

|

5 |

External cooling |

Straight shank |

d1*3*d2*11*5D |

5 |

74 |

34 |

26 |

|||

|

8 |

Internal cooling |

Straight shank |

d113*d2*11*8D-C |

6 |

95 |

57 |

46 |

|||

|

5~6.0 |

3 |

External cooling |

Straight shank |

d1*13*d2*11*3D |

6 |

66 |

28 |

20 |

||

|

5 |

External cooling |

Straight shank |

d1*13*d2*11*5D |

6 |

82 |

42 |

32 |

|||

|

8 |

Internal cooling |

Straight shank |

d1*13*d2*I1*8D-C |

6 |

95 |

57 |

47 |

|||

Applicable table of processed materials

|

number |

Processed materials |

|||||||||

|

Mild steel HB≤ 180 |

Carbon and alloy steels |

Pre hardened steel, hardened steel |

stainless steel |

cast iron |

Ductile iron |

aluminium alloy |

heat- resisting all |

|||

|

~40HRC |

~50HRC |

~60HRC |

||||||||

Remarks:

1.If the 3 or 5 times drill bit needs internal cooling, please make a note when ordering, followed by C;

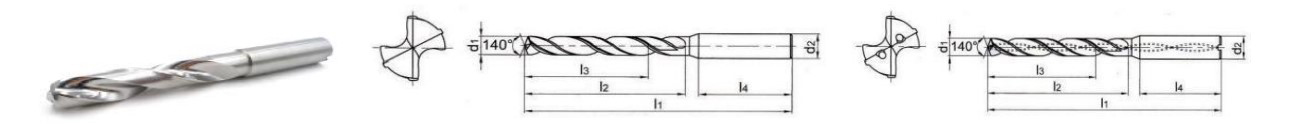

2.The handle is straight by default.If you need other handle standards,please refer to our handle materials or drawings for confirmation; 3.The default top angle is 140 degrees. If other angles are required, please mark or refer to the drawing;

4.If the order parameters are inconsistent with our company’s,you can inform our customer service personnel, and we will be enthusiastic to provide you with drawings for confirmation;

5. The cutter is not coated by default. If coating is required, please inform your requirements or processed materials.