CNC tapping Straight flute tap Solid carbide tap for cast iron coolant tap

- Product description

For users who have the conditions to use coolant during processing, internal coolant carbide tap can be equipped to further enhance the tool life.

OPT provide internal coolant carbide taps and side coolant taps coolant, it depends one the requst of users.

coolant holes serves a vital purpose in extending the tool life of carbide taps.

Firstly, internal coolant holes direct coolant directly to the cutting edges, reducing cutting temperature and friction. This not only helps in preventing the overheating of the tap but also improves chip evacuation.

Secondly, the presence of side coolant holes disperses coolant around the tap shank, further reducing heat buildup and longer the tap's life.

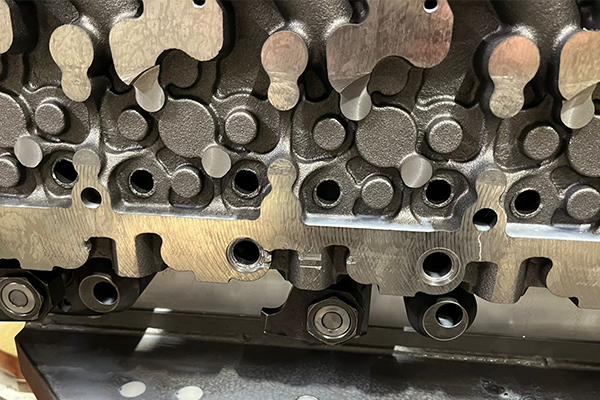

- Typical application

One of the typical application of carbide tap is in machining cast iron engine cylinder heads. These cylinder heads play a pivotal role in the overall performance and durability of engines. With the application of carbide taps, manufacturers achieve superior thread accuracy, resulting in enhanced sealing properties and reduced chances of leakage. Moreover, the extended tool life of carbide taps enables efficient mass production while maintaining consistent quality standards.

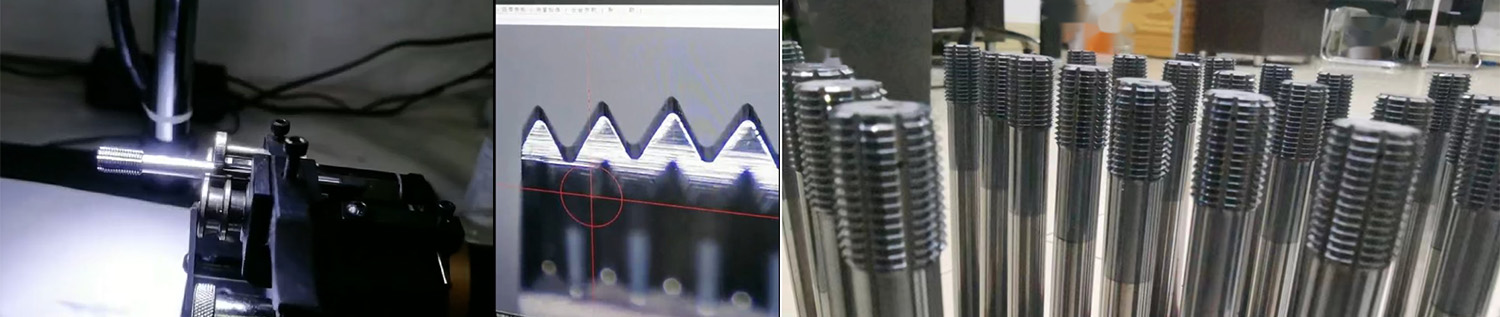

Inspection and display

Before ordering, please communicate with our pre-sales customer service:

1. Workpiece material

2. Whether product is surface treated after processing

3. Accuracy requirements, size of go gauge and no go gauge.

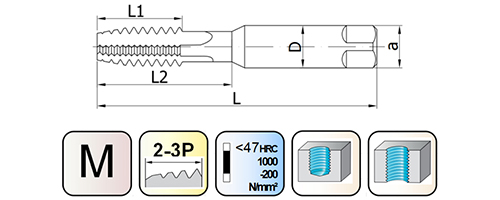

| Designation D |

Thread size |

Pitch mm |

L1 mm |

L2 mm |

D mm |

L mm |

Z |

a ¨ |

Pre-drill mm |

| T602-040048-M3x0.5 |

M3 |

0.5 |

11 |

18 |

4 |

48 |

4 |

3.15 |

2.46-2.59 |

| T602-040050-M3.5×0.6 |

M3.5 |

0.6 |

13 |

21 |

4 |

50 |

4 |

3.15 |

2.85-3.01 |

| T602-050053-M4x0.7 |

M4 |

0.7 |

13 |

21 |

5 |

53 |

4 |

4 |

3.25-3.42 |

| T602-060058-M5x0.8 |

M5 |

0.8 |

16 |

25 |

6 |

58 |

4 |

4.5 |

4.14-4.33 |

| T602-060066-M6x1 |

M6 |

1 |

19 |

30 |

6 |

66 |

4 |

4.5 |

4.92-5.15 |

| T602-080072-M8x1 |

M8 |

1 |

22 |

35 |

8 |

72 |

4 |

6.3 |

6.92-7.15 |

| T602-080072-M8x1.25 |

M8 |

1.25 |

22 |

35 |

8 |

72 |

4 |

6.3 |

6.65-6.91 |

| T602-080080-M10x1 |

M10 |

1 |

24 |

- |

8 |

80 |

4 |

6.3 |

8.92-9.16 |

| T602-100080-M10x1 |

M10 |

1 |

24 |

38 |

10 |

80 |

4 |

8 |

8.92-9.16 |

| T602-080080-M10x1.25 |

M10 |

1.25 |

24 |

- |

8 |

80 |

4 |

6.3 |

8.65-8.91 |

| T602-100080-M10x1.25 |

M10 |

1.25 |

24 |

38 |

10 |

80 |

4 |

8 |

8.65-8.91 |

| T602-080080-M10x1.5 |

M10 |

1.5 |

24 |

- |

8 |

80 |

4 |

6.3 |

8.38-8.67 |

| T602-100080-M10x1.5 |

M10 |

1.5 |

24 |

38 |

10 |

80 |

4 |

8 |

8.38-8.67 |

| T602-100089-M12x1.25 |

M12 |

1.25 |

29 |

- |

10 |

89 |

4 |

8 |

10.65-10.91 |

| T602-120089-M12x1.25 |

M12 |

1.25 |

29 |

46 |

12 |

89 |

4 |

10 |

10.65-10.91 |

| T602-100089-M12x1.5 |

M12 |

1.5 |

29 |

- |

10 |

89 |

4 |

8 |

10.38-10.67 |

| T602-120089-M12x1.5 |

M12 |

1.5 |

29 |

46 |

12 |

89 |

4 |

10 |

10.38-10.67 |

| T602-100089-M12x1.75 |

M12 |

1.75 |

29 |

- |

10 |

89 |

4 |

8 |

10.11-10.44 |

| T602-120089-M12x1.75 |

M12 |

1.75 |

29 |

46 |

12 |

89 |

4 |

10 |

10.11-10.44 |

| T602-120095-M14x1.5 |

M14 |

1.5 |

30 |

- |

12 |

95 |

4 |

10 |

12.38-12.67 |

| T602-120095-M14x2 |

M14 |

2 |

30 |

- |

12 |

95 |

4 |

10 |

11.84-12.2 |

| T602-120102-M16x2 |

M16 |

2 |

32 |

- |

12 |

102 |

4 |

10 |

13.9-14.2 |