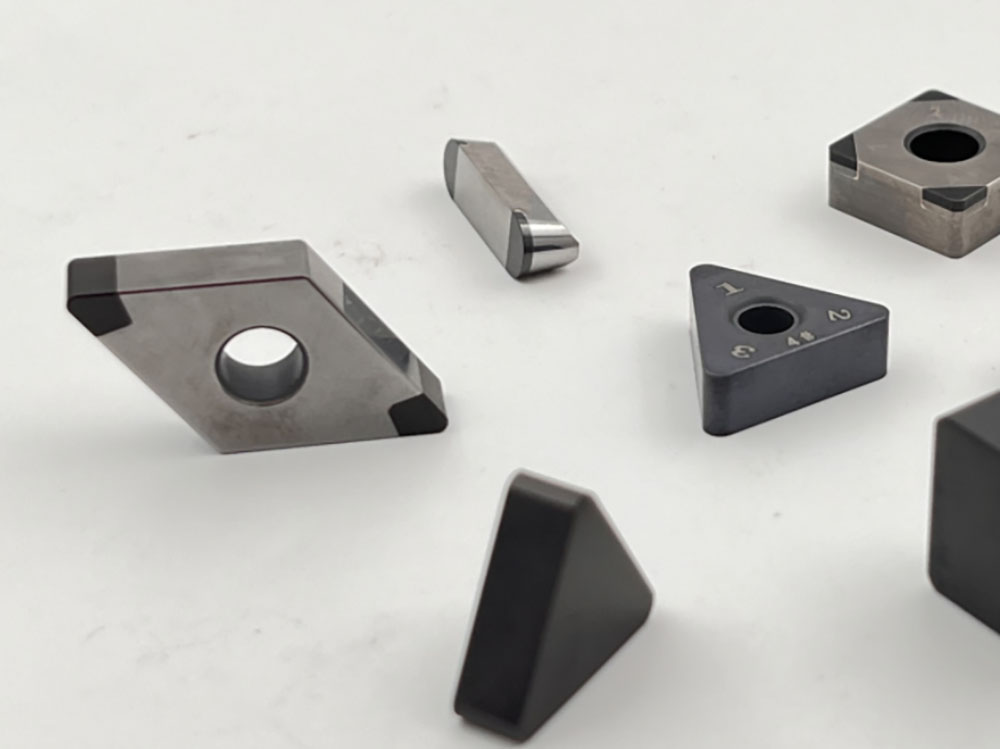

High quality wear-resistant polycrystalline diamond tool blade and CBN insert

CBN inserts have high thermal conductivity and high stability, enabling them to maintain their properties at temperatures up to 1400°C, where diamonds decompose above 800°C. CBN inserts are suitable for high speed cutting and machining of high nickel and chromium cast iron, automotive brake discs, brake drums, cast iron hubs, cast iron rolls, rollers and pumps, etc. CBN inserts can improve surface quality and accuracy, extend tool life and reduce machining costs.

Product advantages

The microhardness of CBN single crystal is HV8000 ~ 9000, and the hardness of PCBN composite sheet is generally HV3000 ~ 5000. Therefore, it has higher wear resistance than hard alloy and ceramics when processing high hardness materials, and can reduce the size deviation in parts processing. It is especially suitable for equipment with high degree of automation, and can reduce the auxiliary

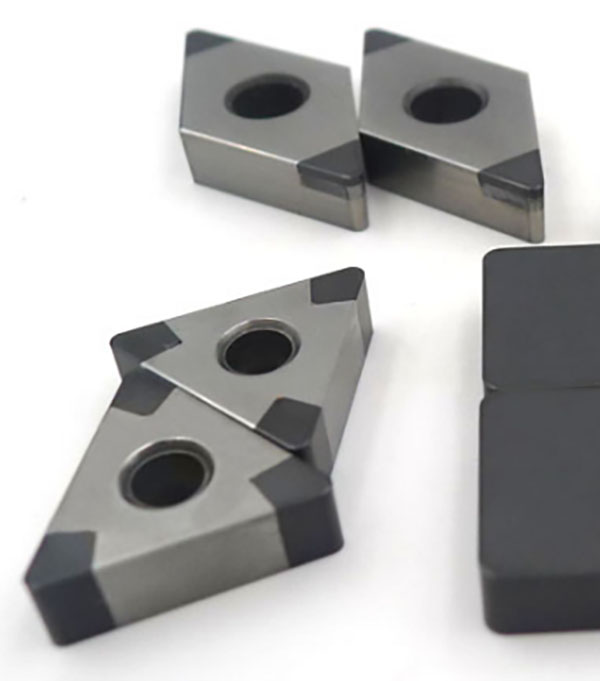

| Insert shape | Type | Grade | |||||||

| d | s | d1 | R | OPT850 | OPT005 | OPT010 | OPT302 | ||

|

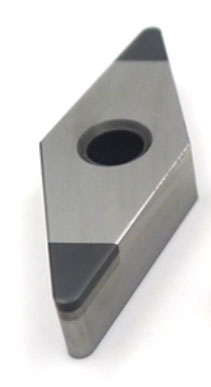

VNGA160402 | 9.525 | 4.76 | 3.81 | 0.2 | ||||

| VNGA160404 | 9.525 | 4.76 | 3.81 | 0.4 | ★ | ||||

| VNGA160408 | 9.525 | 4.76 | 3.81 | 0.8 | ★ | ||||

| VNGA160412 | 9.525 | 4.76 | 3.81 | 1.2 | |||||

| VNGA220408 | 12.7 | 4.76 | 5.16 | 0.8 | |||||

| VNGA220412 | 12.7 | 4.76 | 3.81 | 1.2 | |||||

| VNGA160404-2 | 9.525 | 4.76 | 5.16 | 0.4 | ★ | ||||

| VNGA160408-2 | 9.525 | 4.76 | 5.16 | 0.8 | ★ | ||||

| Insert shape | Type | Dimension(mm) | Grade | |||||||

| L | ¢I.C | S | ¢d | r | OPT850 | OPT005 | OPT010 | OPT302 | ||

|

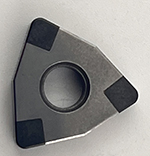

WNGA06T304 | 6.5 | 9.525 | 3.97 | 3.81 | 0.4 | ★ | |||

| WNGA080408 | 8.69 | 12.7 | 4.76 | 5.16 | 0.8 | ★ | ||||

| WNGA080412 | 8.69 | 12.7 | 4.76 | 5.16 | 1.2 | ★ | ||||

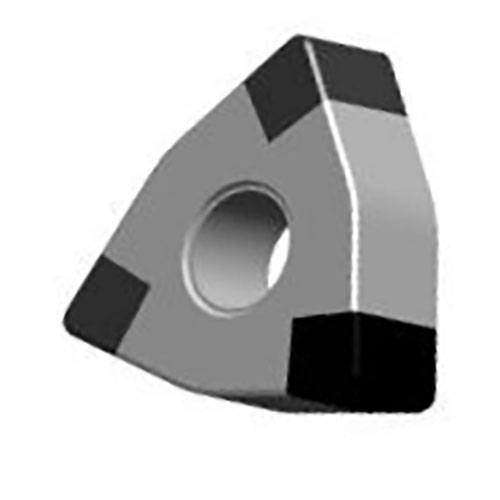

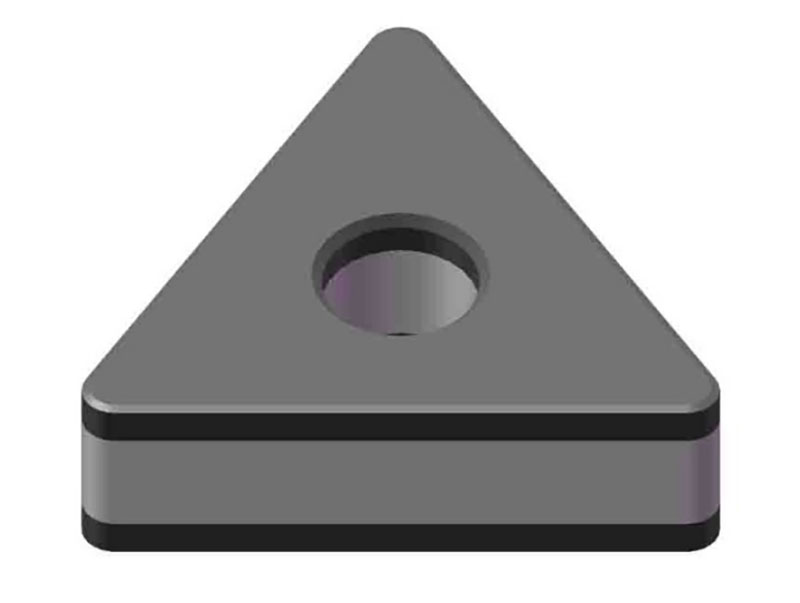

| Insert shape | Type | Grade | |||||||

| d | s | d1 | R | OPT850 | OPT005 | OPT010 | OPT302 | ||

|

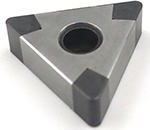

TNGA160402 | 9.525 | 4.76 | 3.81 | 0.2 | ||||

| TNGA160404 | 9.525 | 4.76 | 3.81 | 0.4 | 〇 | ★ | |||

| TNGA160408 | 9.525 | 4.76 | 3.81 | 0.8 | 〇 | ★ | |||

| TNGA160412 | 9.525 | 4.76 | 3.81 | 1.2 | 〇 | ★ | |||

| TNGA160416 | 9.525 | 4.76 | 3.81 | 1.6 | |||||

| TNGA220404 | 12.7 | 4.76 | 5.16 | 0.4 | |||||

| TNGA220408 | 12.7 | 4.76 | 5.16 | 0.8 | 〇 | ★ | |||

| TNGA220412 | 12.7 | 4.76 | 5.16 | 1.2 | 〇 | ★ | |||

| Insert shape | Type | Grade | |||||||

| d | s | d1 | R | OPT850 | OPT005 | OPT010 | OPT302 | ||

|

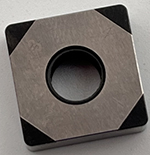

SNGA090304 | 9.525 | 3.18 | 3.81 | 0.4 | ★ | |||

| SNGA090308 | 9.525 | 3.18 | 3.81 | 0.8 | ★ | ||||

| SNGA120404 | 12.7 | 4.76 | 5.16 | 0.4 | ★ | ||||

| SNGA120408 | 12.7 | 4.76 | 5.16 | 0.8 | ★ | ||||

| SNGA120412 | 12.7 | 4.76 | 5.16 | 1.2 | |||||

| Insert shape | Type | Grade | |||||||

| d | s | d1 | R | OPT850 | OPT005 | OPT010 | OPT302 | ||

|

CNGA09T302 | 9.525 | 3.97 | 3.81 | 0.2 | ★ | |||

| CNGA09T304 | 9.525 | 3.97 | 3.81 | 0.4 | ★ | ||||

| CNGA09T308 | 9.525 | 3.97 | 3.81 | 0.8 | |||||

| CNGA09T312 | 9.525 | 3.97 | 3.81 | 1.2 | |||||

| CNGA120402 | 12.7 | 4.76 | 5.16 | 0.2 | ★ | ||||

| CNGA120404 | 12.7 | 4.76 | 5.16 | 0.4 | ★ | ||||

| CNGA120408 | 12.7 | 4.76 | 5.16 | 0.8 | |||||

| CNGA120412 | 12.7 | 4.76 | 5.16 | 1.2 | |||||