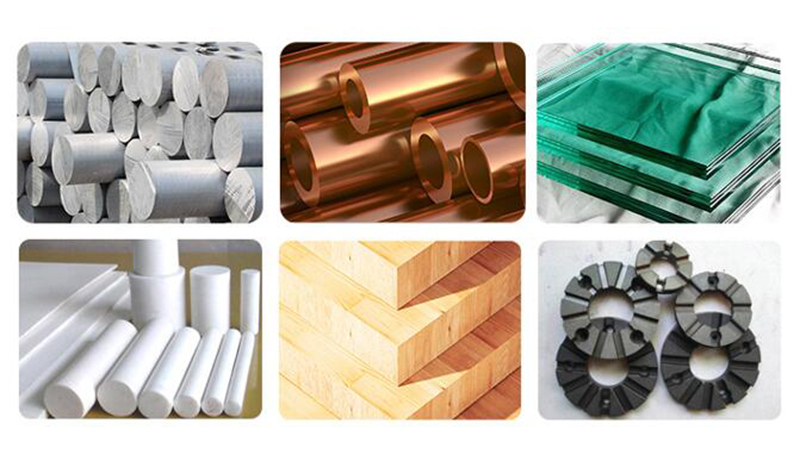

High Quality Wear resistant Polycrystalline diamond tools inserts blades Turning milling cutting PCD insert

Product advantages

Key Features and Benefits

1. PCD blade, high efficiency, long life.

2. It can make the chip removal of inner hole processing more smooth and meet the requirements of high machining surface.

3. It can prevent tool damage, tool bar breakage and workpiece scrapping caused by unsmooth chip removal.

4. Effectively deal with problems such as chip wrapping and chip scratching on workpiece surface in automatic production line.

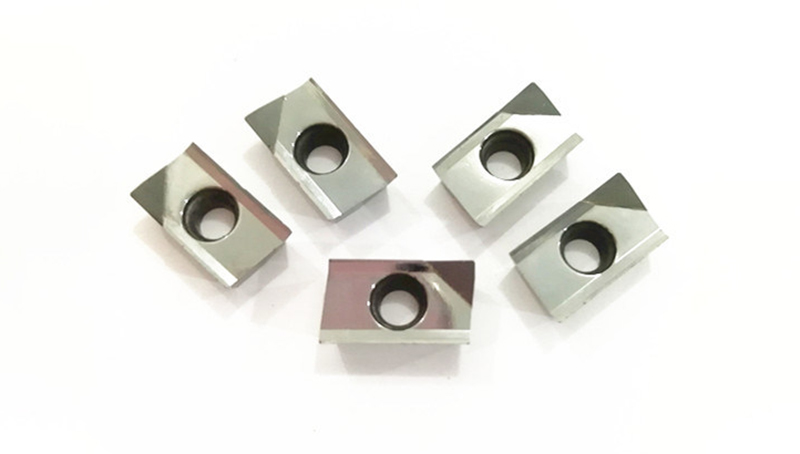

Choose a good full side PCD insert and get twice the result with half the effort

Use effect of OPT Full face PCD insert

1. Low processing cost

2. Long service life

3. The turning and milling effect is bright

4. Long continuous processing time The OPT blade is processed continuously for 400 minutes, and the blade is normally worn without breakage

Superior performance, complete specifications, and direct sales of cutters by manufacturers

High speed, high productivity, high-speed cutting High gloss effect and high finish. The processed products do not need polishing, and can also achieve the high gloss plane effect, with high smoothness. Shenzhen cutter factory price, complete specifications, low price, cost-effective!

The Milling PCD insert High quality, low price

10 years of domestic cutter production experience. High quality, factory price

The PCD insert are constantly improved and optimized, and German equipment is introduced to improve the production process. The wear resistance and finish are well known in the industry Professional design and testing team can customize the processing scheme

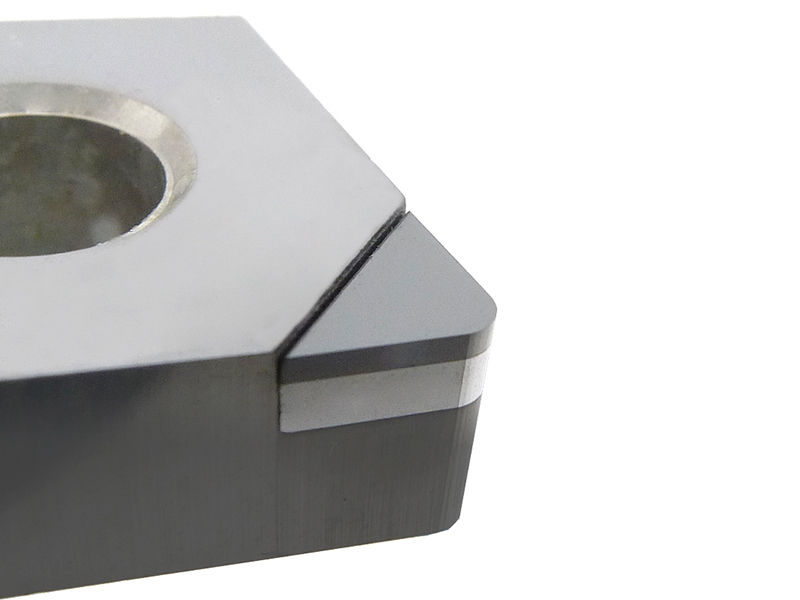

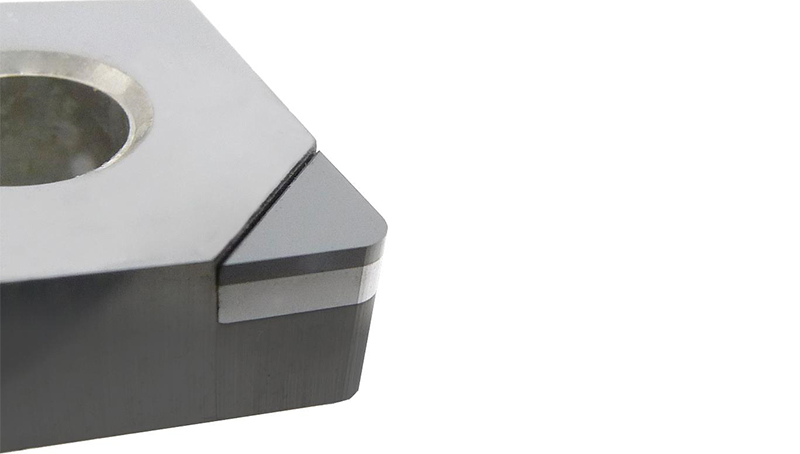

The Diamond insert High precision

The preset position surface can make the blade locate quickly, and the positioning accuracy can reach 0.02mm, meeting the needs of many users without preset equipment The runout adjustment is simple and convenient, and the adjustment range is within 0.1mm. The special and simple adjustment structure enables the whole disc blade to be adjusted to an accuracy of less than 2 microns.

|

Dimension, mm |

|||||

|

Series |

Model No. |

d |

S |

d1 |

R |

|

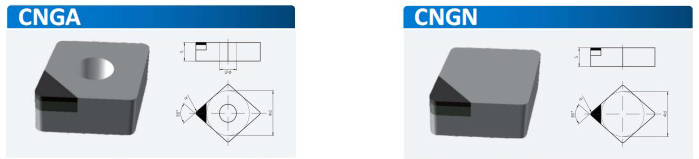

CNGA |

CNGA09T302 |

9.525 |

3.97 |

3.81 |

0.2 |

|

CNGA09T304 |

9.525 |

3.97 |

3.81 |

0.4 |

|

|

CNGA09T308 |

9.525 |

3.97 |

3.81 |

0.8 |

|

|

CNGA09T312 |

9.525 |

3.97 |

3.81 |

1.2 |

|

|

CNGA120402 |

12.7 |

4.76 |

5.16 |

0.2 |

|

|

CNGA120404 |

12.7 |

4.76 |

5.16 |

0.4 |

|

|

CNGA120408 |

12.7 |

4.76 |

5.16 |

0.8 |

|

|

CNGA120412 |

12.7 |

4.76 |

5.16 |

1.2 |

|

|

Series |

Model No. |

d |

S |

d1 |

R |

|

CNGN |

CNGN120404 |

12.7 |

4.76 |

- |

0.4 |

|

CNGN120408 |

12.7 |

4.76 |

- |

0.8 |

|

|

CNGN120412 |

12.7 |

4.76 |

- |

1.2 |

|

|

CNGN120416 |

12.7 |

4.76 |

- |

1.6 |

|

|

Dimension, mm |

|||||

|

Series |

Model No. |

d |

S |

d1 |

R |

|

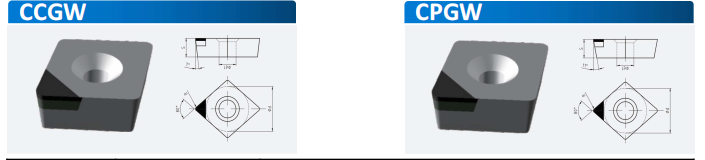

CCGW |

CCGW060202 |

6.35 |

2.38 |

2.8 |

0.2 |

|

CCGW060204 |

6.35 |

2.38 |

2.8 |

0.4 |

|

|

CCGW060208 |

6.35 |

2.38 |

2.8 |

0.8 |

|

|

CCGW09T304 |

9.525 |

3.97 |

4.4 |

0.4 |

|

|

CCGW09T308 |

9.525 |

3.97 |

4.4 |

0.8 |

|

|

CCGW120404 |

12.7 |

4.76 |

5.5 |

0.4 |

|

|

CCGW120408 |

12.7 |

4.76 |

5.5 |

0.8 |

|

|

CCGW120412 |

12.7 |

4.76 |

5.5 |

1.2 |

|

|

Series |

Model No. |

d |

S |

d1 |

R |

|

CPGW |

CPGW060202 |

6.35 |

2.38 |

2.8 |

0.2 |

|

CPGW060204 |

6.35 |

2.38 |

2.8 |

0.4 |

|

|

CPGW060208 |

6.35 |

2.38 |

2.8 |

0.8 |

|

|

CPGW09T304 |

9.525 |

3.97 |

4.4 |

0.4 |

|

|

CPGW09T308 |

9.525 |

3.97 |

4.4 |

0.8 |

|

|

CPGW120404 |

12.7 |

4.76 |

5.5 |

0.4 |

|

|

CPGW120408 |

12.7 |

4.76 |

5.5 |

0.8 |

|

|

CPGW120412 |

12.7 |

4.76 |

5.5 |

1.2 |

|