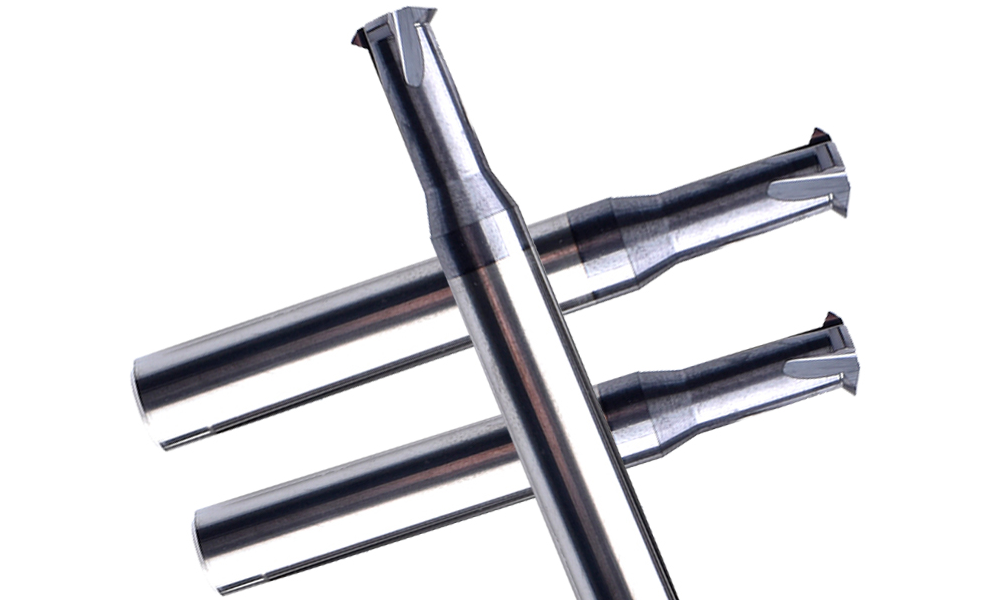

Analysis of the advantages of tungsten steel milling cutters to improve processing quality and efficiency! Tungsten steel milling cutter is a commonly used machining tool with many advantages, which can greatly improve machining quality and efficiency. Let’s carefully analyze it below.

Firstly, tungsten steel milling cutters have high hardness and wear resistance. Tungsten steel is made by combining tungsten with metal alloys such as cobalt or nickel, and its hardness is extremely high, which can resist the wear of most metal materials. Therefore, tungsten steel milling cutters have withstood the test of time and materials during the processing process. This is also why tungsten steel milling cutters can maintain sharpness and not deteriorate after prolonged use.

Secondly, tungsten steel milling cutters have high strength and rigidity. Due to the high strength and rigidity of tungsten steel, tungsten steel milling cutters are less prone to deformation and breakage, making them more stable and reliable during the machining process. For example, when processing deep holes and other tasks, some low-quality milling cutters are prone to vibration and deformation, leading to a decrease in processing quality. Tungsten steel milling cutters, due to their high hardness, strength, and good rigidity, can effectively solve these problems.

Thirdly, tungsten steel milling cutters have strong cutting ability. Due to the high hardness of tungsten steel milling cutters, they can better cut metal materials, improve machining efficiency and speed. Therefore, during the processing process, unnecessary processing times and technical processes can be reduced to a certain extent, thereby saving time and costs.

Fourthly, tungsten steel milling cutters have excellent cutting surface effects. Due to the good cutting performance of tungsten steel milling cutters, they can cut ideal cutting surfaces, ensure the flatness and smoothness of the workpiece surface, and improve machining accuracy and quality. This is very important for the processing of high-precision mechanical components.

Overall, tungsten steel milling cutters have many advantages and can play a crucial role in the machining process, improving machining efficiency and quality. Therefore, when selecting machining tools, it is necessary to choose the tool that is suitable for oneself based on the actual situation, and at the same time, it is necessary to have a targeted understanding and mastery of the parameters and characteristics of the tool before use, in order to fully utilize the advantages of tungsten steel milling cutters.

Finally, it is worth noting that safety also needs to be taken into account when using tungsten steel milling cutters. Due to the strong hardness and cutting ability of tungsten steel milling cutters, it is necessary to wear safety protection equipment during use to ensure personnel safety. At the same time, attention should also be paid to the protection and maintenance of the machining surface.

Post time: Aug-02-2023