When we tapping threads, there are many types of taps for you to choose from?

How do we choose a tool that suits us? Such as tapping hardened steel, tapping cast iron, or tapping aluminum, how should we do?

We can choose threading taps based on the following tips

1. The type of threads, Metric thread taps, UN thread taps, such as M/MF/MJUN/UNC/UNF/UNS/NPT/NPTFG/BSW/BSP/BSPT

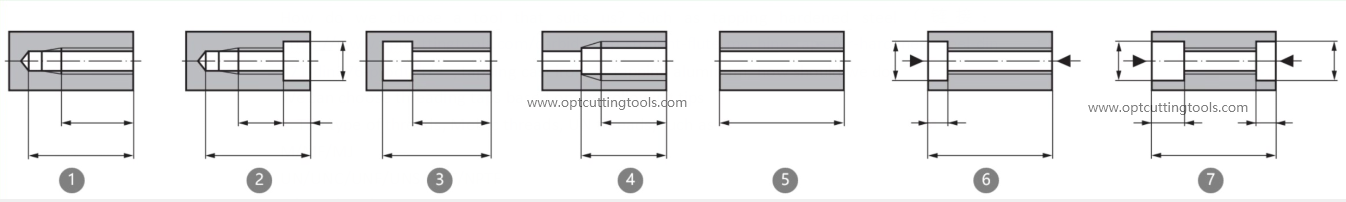

2.The type of threaded bottom hole, through hole or blind hole;

3. The material and hardness of the workpiece;

4.Depth of the thread and size of bottom hole of the workpiece, the hole type, internal coolant needed or not?

5.Accuracy of the workpiece thread;

Tips: The accuracy level of the tap cannot be selected and determined solely based on the accuracy level of the processed thread

The following factors also need to be considered:

The material and hardness of the processed workpiece;

Tapping equipment (such as machine tool conditions, clamping tool handles, cooling environment, etc.);

The accuracy and the tolerance of the tap itself.

For example, when processing 6H threads on steel parts, a 6H standard tap can be selected; When processing gray cast iron, due to the rapid wear of the pitch diameter of the tap and the small expansion of the screw hole, it is advisable to choose a 6HX precision tap for better service life.

6. The specification of the tap (special requirements need to be considered).

Post time: Oct-23-2023