With the development of modern science and technology, more and more engineering materials with high hardness are used, while the traditional turning technology is not competent or can not achieve the processing of some high hardness materials at all. Coated carbide, ceramics, PCBN and other superhard tool materials have high high temperature hardness, wear resistance and thermochemical stability, which provide the most basic prerequisite for the cutting of high hardness materials, and have achieved significant benefits in production. The material used by the superhard tool and its tool structure and geometric parameters are the basic elements to realize hard turning. Therefore, how to select the superhard tool material and design a reasonable tool structure and geometric parameters is crucial to achieve stable hard turning!

(1) Coated cemented carbide

Apply one or more layers of TiN, TiCN, TiAlN and Al3O2 with good wear resistance on cemented carbide tools with good toughness, and the thickness of the coating is 2-18 μ m. The coating usually has a much lower thermal conductivity than the tool substrate and workpiece material, which weakens the thermal effect of the tool substrate; On the other hand, it can effectively improve the friction and adhesion in the cutting process and reduce the generation of cutting heat.

Although PVD coating shows many advantages, some coatings such as Al2O3 and diamond tend to adopt CVD coating technology. Al2O3 is a kind of coating with strong heat resistance and oxidation resistance, which can separate the heat generated by cutting from the specific tool. CVD coating technology can also integrate the advantages of various coatings to achieve the best cutting effect and meet the needs of cutting.

Compared with cemented carbide tools, coated cemented carbide tools have greatly improved in strength, hardness and wear resistance. When turning the workpiece with hardness of HRC45~55, low-cost coated cemented carbide can realize high-speed turning. In recent years, some manufacturers have improved the performance of coated tools by improving coating materials and other methods. For example, some manufacturers in the United States and Japan use Swiss AlTiN coating material and new coating patented technology to produce coated blades with hardness as high as HV4500~4900, which can cut HRC47~58 die steel at a speed of 498.56m/min. When the turning temperature is up to 1500~1600 ° C, the hardness still does not decrease and does not oxidize. The service life of the blade is four times that of the general coated blade, while the cost is only 30%, and the adhesion is good.

(2) Ceramicmaterial

With the continuous improvement of its composition, structure and pressing process, especially the development of nanotechnology, ceramic tool materials make it possible to toughen ceramic tools. In the near future, ceramics may cause the third revolution in cutting after high-speed steel and cemented carbide. Ceramic tools have the advantages of high hardness (HRA91~95), high strength (bending strength 750~1000MPa), good wear resistance, good chemical stability, good adhesion resistance, low friction coefficient and low price. Not only that, ceramic tools also have high high temperature hardness, which reaches HRA80 at 1200 ° C.

During normal cutting, the ceramic tool has a very high durability, and its cutting speed can be 2~5 times higher than that of cemented carbide. It is especially suitable for machining high hardness materials, finishing and high-speed machining. It can cut various hardened steel and hardened cast iron with hardness up to HRC65. Commonly used are alumina based ceramics, silicon nitride based ceramics, cermets and whisker toughened ceramics.

Alumina-based ceramic tools have higher red hardness than cemented carbide. Generally, the cutting edge will not produce plastic deformation under high-speed cutting conditions, but its strength and toughness are very low. In order to improve its toughness and impact resistance, ZrO or TiC and TiN mixture can be added. Another method is to add pure metal or silicon carbide whiskers. In addition to high red hardness, silicon nitride based ceramics also have good toughness. Compared with alumina based ceramics, its disadvantage is that it is easy to produce high temperature diffusion when machining steel, which aggravates tool wear. Silicon nitride based ceramics are mainly used for intermittent turning and milling of gray cast iron.

Cermet is a kind of carbide-based material, in which TiC is the main hard phase (0.5-2 μm) They are combined with Co or Ti binders and are similar to cemented carbide tools, but they have low affinity, good friction and good wear resistance. It can withstand higher cutting temperature than conventional cemented carbide, but it lacks the impact resistance of cemented carbide, the toughness during heavy cutting and the strength at low speed and large feed.

(3) Cubic boron nitride (CBN)

CBN is second only to diamond in hardness and wear resistance, and has excellent high temperature hardness. Compared with ceramics, its heat resistance and chemical stability are slightly poor, but its impact strength and anti-crushing performance are better. It is widely applicable to the cutting of hardened steel (HRC ≥ 50), pearlitic gray cast iron, chilled cast iron and superalloy. Compared with cemented carbide tools, its cutting speed can be increased by one order of magnitude.

The composite polycrystalline cubic boron nitride (PCBN) tool with high CBN content has high hardness, good wear resistance, high compressive strength and good impact toughness. Its disadvantages are poor thermal stability and low chemical inertness. It is suitable for cutting heat-resistant alloys, cast iron and iron-based sintered metals. The content of CBN particles in PCBN tools is low, and the hardness of PCBN tools using ceramics as binder is low, but it makes up for the poor thermal stability and low chemical inertia of the former material, and is suitable for cutting hardened steel.

When cutting gray cast iron and hardened steel, ceramic tool or CBN tool can be selected. For this reason, cost-benefit and processing quality analysis should be carried out to determine which one to choose. When the cutting hardness is lower than HRC60 and small feed rate is adopted, ceramic tool is a better choice. PCBN tools are suitable for cutting workpieces with hardness higher than HRC60, especially for automatic machining and high-precision machining. In addition, the residual stress on the workpiece surface after cutting with PCBN tool is also relatively stable than that with ceramic tool under the condition of the same flank wear.

When using PCBN tool to dry cut hardened steel, the following principles should also be followed: select a large cutting depth as far as possible under the condition that the rigidity of the machine tool allows, so that the heat generated in the cutting area can soften the metal in the front of the edge locally, which can effectively reduce the wear of PCBN tool. In addition, when using a small cutting depth, it should also be considered that the poor thermal conductivity of PCBN tool can make the heat in the cutting area too late to diffuse, and the shear area can also produce obvious metal softening effect, Reduce the wear of cutting edge.

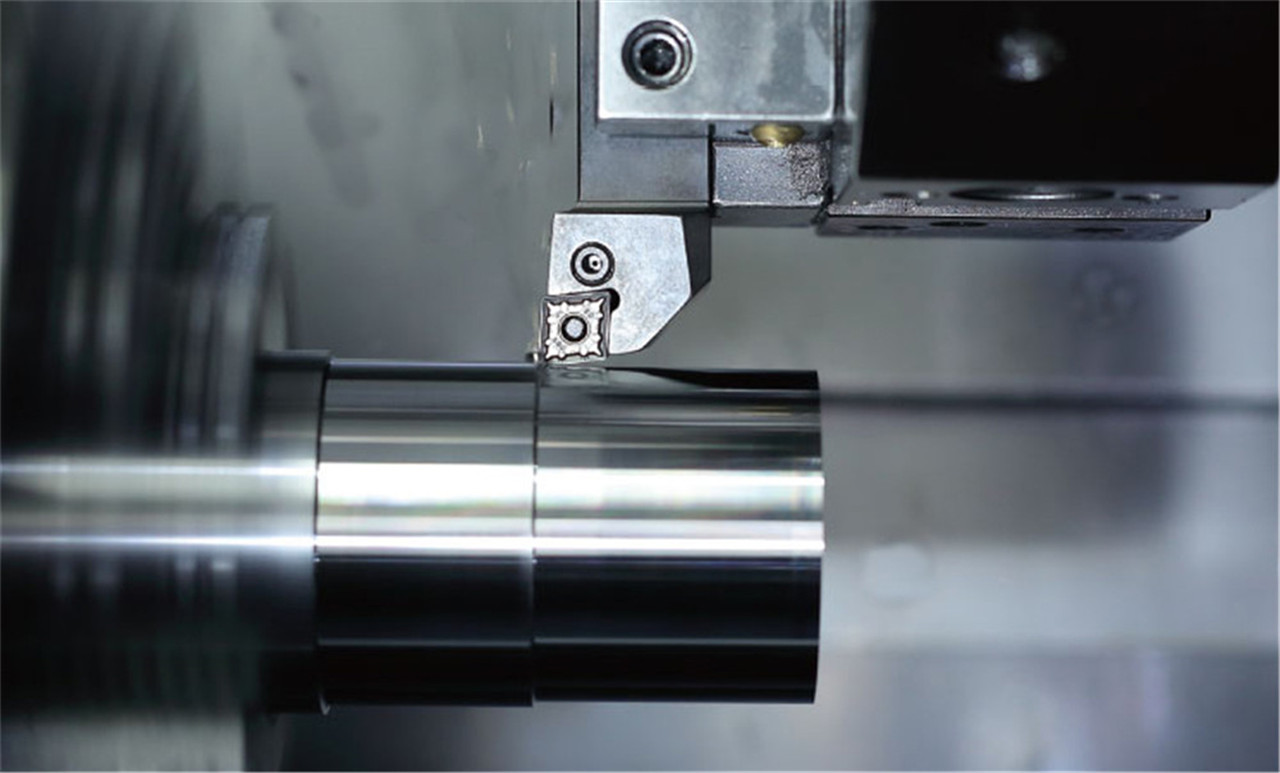

2. Blade structure and geometric parameters of superhard tools

The reasonable determination of the shape and geometric parameters of the tool is very important to give full play to the cutting performance of the tool. In terms of tool strength, the tool tip strength of various blade shapes from high to low is: round, 100 ° diamond, square, 80 ° diamond, triangle, 55 ° diamond, 35 ° diamond. After the blade material is selected, the blade shape with the highest strength shall be selected. Hard turning blades should also be selected as large as possible, and rough machining should be done with circular and large tip arc radius blades. The tip arc radius is about 0.8 when finishing μ About m.

The hardened steel chips are red and soft ribbons, with great brittleness, easy to break and non-binding. The hardened steel cutting surface is of high quality and generally does not produce chip accumulation, but the cutting force is large, especially the radial cutting force is larger than the main cutting force. Therefore, the tool should use a negative front angle (go ≥ - 5 °) and a large back angle (ao=10°~15°). The main deflection angle depends on the rigidity of the machine tool, generally 45 °~60 °, to reduce the chatter of the workpiece and tool.

Post time: Feb-24-2023