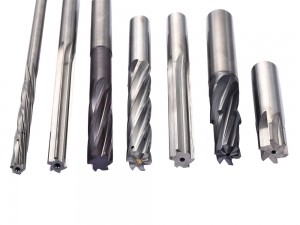

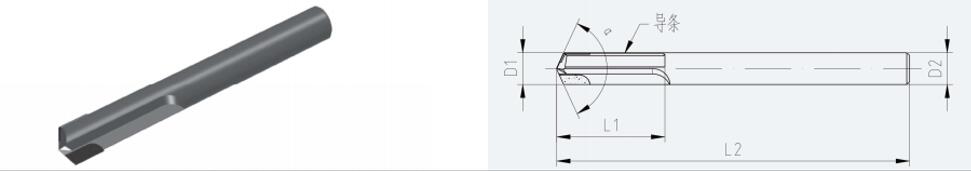

PCD reamer drill bit

1.The reamer is designed for the processing of nozzle hole, with unique chip discharging slot and internal cooling setting; It can not only satisfy the hole size accuracy and smoothness, but also ensure the coaxiality between the holes.

2.If the tool is designed with internal cooling, it is conducive to the discharge of chips.

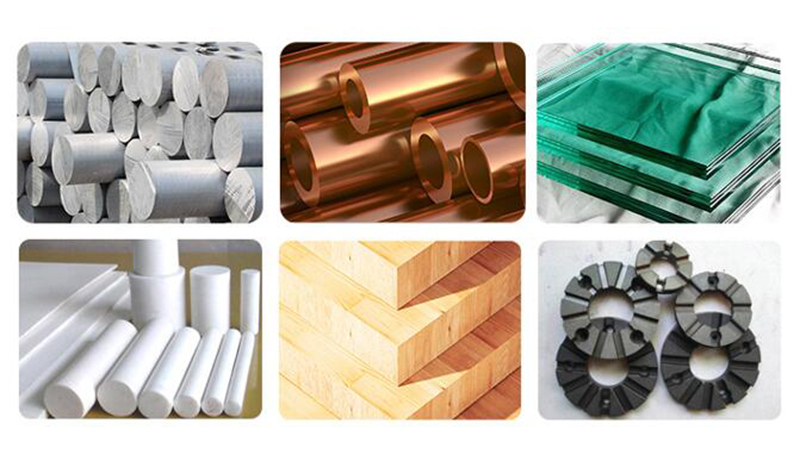

pcd reamer has fast processing speed, high production capacity and good product quality in aluminum alloy and non-ferrous metals or wood. Carbon fiber and non - iron metal industry, can better replace tungsten steel tools! Is the choice of modern machining to improve efficiency,pcd tool is both environmentally friendly and reliable.

PCD dril reamer

|

Model No. |

Dimension, mm |

Material |

||||

|

d1 |

d2(H6) |

11 |

I2 |

a |

||

|

RZ0400060080LP2001 |

4 |

6 |

40 |

80 |

130° |

PCD |

|

RZ0500060080LP2001 |

5 |

6 |

40 |

80 |

130° |

PCD |

|

RZ0600060080LP2001 |

6 |

6 |

40 |

80 |

130° |

PCD |

|

RZ0700080080LP2001 |

7 |

8 |

40 |

80 |

130° |

PCD |

|

RZ0800080080LP2001 |

8 |

8 |

40 |

80 |

130° |

PCD |

|

RZ0900100080LP2001 |

9 |

10 |

40 |

80 |

130° |

PCD |

|

RZ1000100080LP2001 |

10 |

10 |

40 |

80 |

130° |

PCD |

|

RZ1200120080LP2001 |

12 |

12 |

40 |

80 |

130° |

PCD |

|

RZ1400140080LP2001 |

14 |

14 |

40 |

80 |

130° |

PCD |

|

RZ1500160080LP2001 |

15 |

16 |

40 |

80 |

130° |

PCD |