PCD Turning Grooving Inserts PCD external grooving inserts diamond large allowance turning groove tools

Product advantages

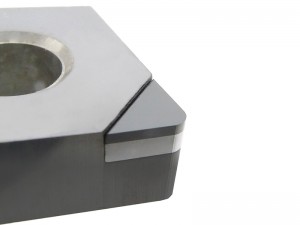

Technical upgrading, good flatness

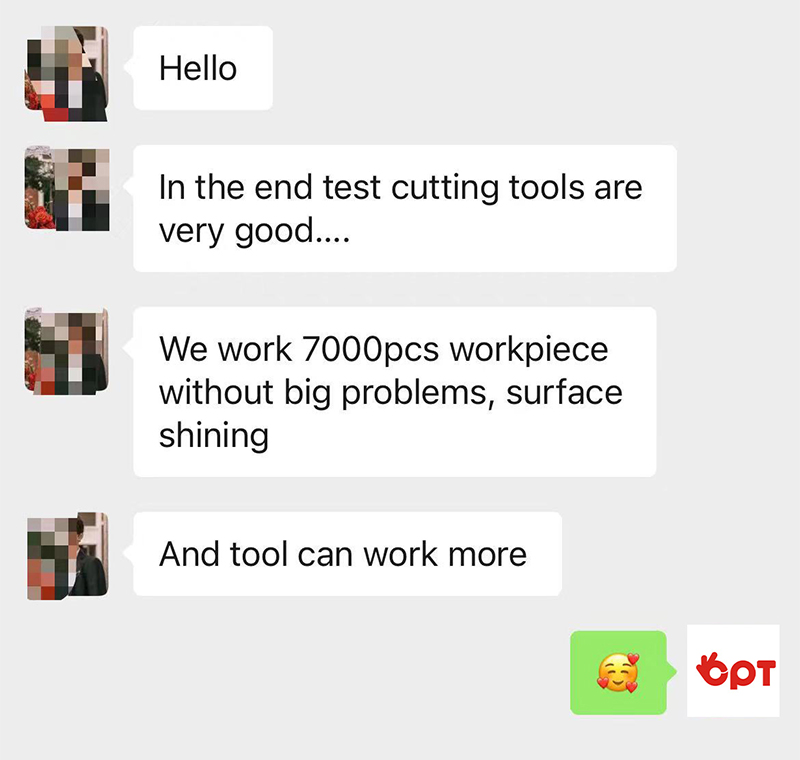

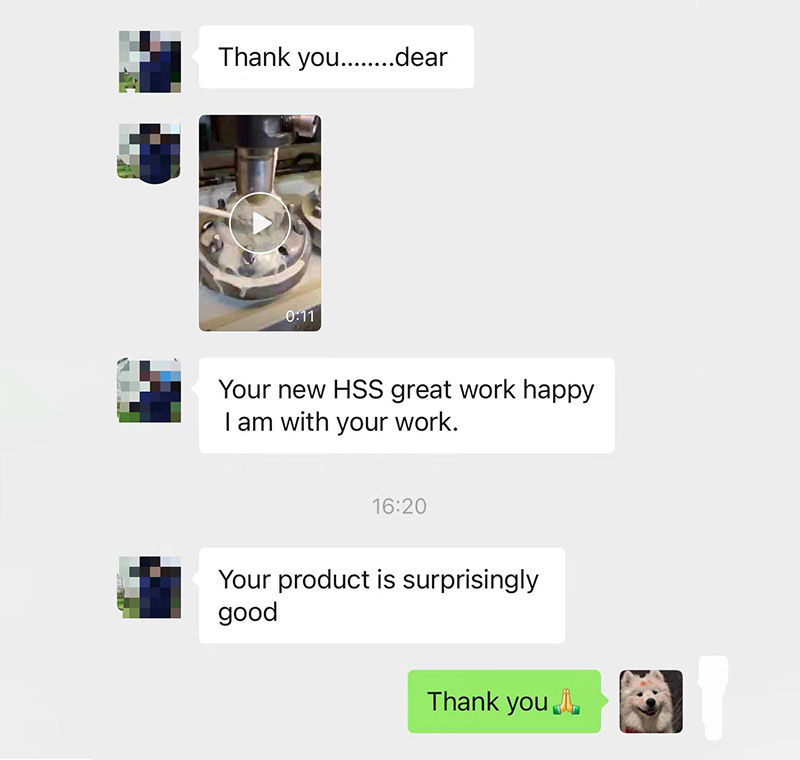

Because the friction coefficient is reduced, the cutting resistance is reduced and sharp cutting is realized. The cutting edge has extremely high wear resistance and toughness, high hardness, high thermal conductivity, and low thermal expansion coefficient. The vacuum welding knife edge is firm and reliable, and the knife does not jump.

PCD piston bits Sophisticated technology, sharp and wear-resistant

The overall hardness of the blade is stronger, the cutting edge is sharper, and the service life is longer The blade is sharp and the resistance is small. Enhanced cutting edge makes cutting more stable and chip removal faster. The cutting edge is sharp and smooth, wear-resistant and heat-resistant

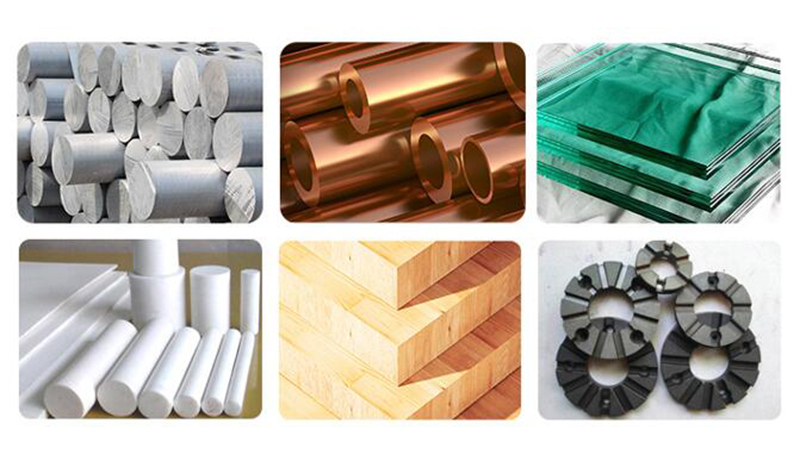

Our PCD grooving tool for piston have Strict material selection

High quality synthetic diamond is used to ensure the service life of the tool. The tool is sharp and wear-resistant, with high hardness, high compressive strength, strong thermal conductivity and wear resistance. The processing materials can achieve the mirror effect. Fast cutting speed, high deburring rate of workpiece material.

External Grooving Tool use High quality synthetic diamond, processing without deformation

It is refined by selecting high-quality diamond. The cutting heat is easy to dissipate. The cutting temperature of the blade is low. The high-efficiency machining blade is not deformed, wear-resistant, and has a long service life.

|

Type |

Dimension(mm) |

Grade |

||||||||

|

L |

QI.C |

S |

d |

r |

OPT850 |

OPT005 |

OPTO10 |

OPT302 |

||

|

MGMN |

200-02-L |

2.0 |

0.2 |

20 |

1.7 |

- |

★ |

|||

|

300-02-L |

2.0 |

0.2 |

20 |

2.3 |

- |

★ |

||||

|

400-02-L |

4.0 |

0.2 |

20 |

3.3 |

- |

★ |

||||

|

500-03-L |

5.0 |

0.3 |

25 |

4.1 |

- |

★ |

||||

|

600-03-L |

6.0 |

0.3 |

25 |

5.1 |

- |

★ |

||||