Carbide tap for hardened steel Straight flute Metric tap, UNC tap

- Product description

Taps made of HSSE or HSSE-PM materials are only suitable for processing materials with a hardness below HRC49. Therefore, for workpieces outside this hardness range, carbide tap become the preferred processing choice.

OPT carbide tap for hardened steel with its specially germery of flute profiles and its special rake and relief angles makes thread cutting hardness steel long last, it is apply to workpiece hardness of HRC55-63

TiCN or ALTiN is applied to enhances the hardness and wear resistance improves tool life.

According to end user's application, the Chamfer form leader usually can be 2-3 threads or 4-5 threads, it usually to be used on CNC machining, tap set also available for manuel use.

- Typical application

In recent years, the demand for precision machining of components made from hardened steel has grown exponentially. The increased utilization of hardened steel in industries such as automotive, aerospace, and manufacturing necessitates the use of specialized tools that can effectively handle high hardness levels. Carbide taps designed specifically for hardened steel applications have become indispensable in this regard.

It is important to select a appropriate carbide tap for each specific application.

OPT has been committed to thread machining in a variety of industries, according to customer application matching machining solutions, to bring customers better processing results and production efficiency.

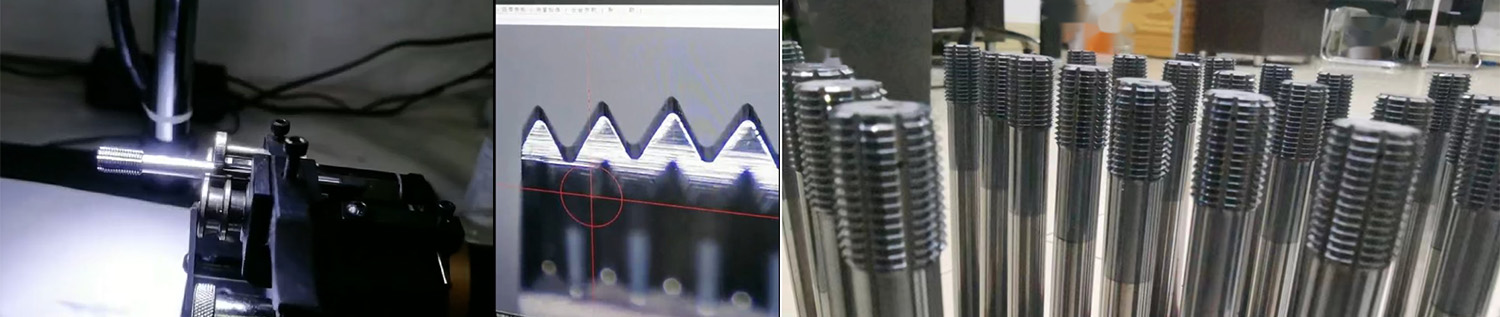

Inspection and display

Before ordering, please communicate with our pre-sales customer service:

1. Workpiece material

2. Whether product is surface treated after processing

3. Accuracy requirements, size of go gauge and no go gauge.